YOUSEF S AL SULTAN TRADING EST. is a General Trading company operating in Dammam, Kingdom of Saudi Arabia, and A region traditionally associated with technical innovation and engineering skills.

We are a network of traders and importers joining our hands together to offer exceptional and trustworthy service. Our culture, enthusiasm and knowledge in the business give our clients the assurance to rely on us. Our aim is to work with our clients embracing their unique requirements to developed products meeting their individual need in a diverse environment.

Our mission is to provide maximum value of customers through the continuous pursuits of improvement programs in areas of service quality and coast.

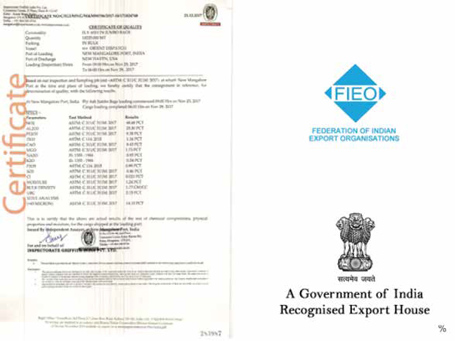

We are importers of quality enriched CLASS F FLY ASH based in Karnataka, India. We import fly ash as per ASTM C618 CLASS F and super fine Fly Ash as per BS3892 PART-1 standard from various countries. We have full pledged bagging unit with the capacity of bagging 5bags/cycle. This unit is within the premises of UPCL ADANI POWER PLANT at the silos to procure direct as from ESP.

FLY ASH

Fly Ash is a byproduct of coal based thermal power station generated by the combustion of pulverised coal. Fly Ash is a fine, grey, amorphous powder. It is rich in all silica & alumina and spherical in shape. the properties of fly ash may vary widely, both physically and chemically, depending upon the nature of coal, the efficiency of coal combustion process and the selection process, therefore, it is important that when considering the use of fly Ash to look no further than a company with the in depth technical knowledge and support to manufacture and supply a high quality product.

Fly Ash is a byproduct of coal based thermal power station generated by the combustion of pulverised coal. Fly Ash is a fine, grey, amorphous powder. It is rich in all silica & alumina and spherical in shape. the properties of fly ash may vary widely, both physically and chemically, depending upon the nature of coal, the efficiency of coal combustion process and the selection process, therefore, it is important that when considering the use of fly Ash to look no further than a company with the in depth technical knowledge and support to manufacture and supply a high quality product.

We only select Fly Ash that is highly reactive and has water reducing characteristics. Our Fly Ash is among the first classified and processed material being made available in India. By classifying and processing, we ensure that a large proportion of our Fly Ash id composed of fine particles, which results in a more controlled and consistent product. Our Fly Ash complies with the stringent international code of practice as BS 3892 PART 1, ASTM C 618, and BF EN 450 & IS 3812 Grade. Our Customers can therefore be assured of the highest standards of quality, process control and product consistency.

CLASS FLY ASH

Class Fly ash is available in the largest quantities Class F is generally low in lime, usually under 15% and contains a greater combination of silica, alumina and iron (greater than 70%) than class C fly ash.

Class Fly ash is available in the largest quantities Class F is generally low in lime, usually under 15% and contains a greater combination of silica, alumina and iron (greater than 70%) than class C fly ash.

1. Most effectively moderates heat gain during concrete curing and is therefore considered an ideal cementitious material in mass concrete and high strength mixes. For the same reason, class F is the solution to a wide range of summer concreting problems.

2. Provides sulfide and sulfate resistance equal or superior to type V cement. Class F is often recommended for use where concrete may be exposed to sulfate ions in soil and ground water.

Concrete manufacturers, engineers, architects, developers and contractor all have an interest in specifying or using fly on a routine basis to improve the quality of their project and to increase their cost effectiveness.

CHARACTERISTICS OF FLY ASH

CHARACTERISTICS OF FLY ASH

• Low Carbon Content

• Spherical particle Shape

• Fine Particle Sizw

• Pozzolonic Reaction

APPLICATIONS

• Cement

• Ready Mix

• Construction Industry

• Pre Cast

• Aerated Autoclave Technology

• Oil Rigs

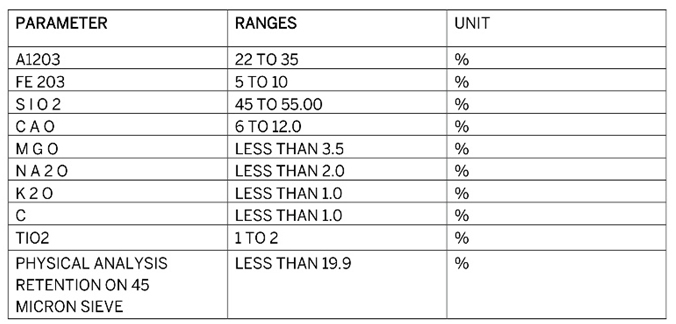

SPECIFICATION

BENTONITE

Bentonite is a clay generated frequently from the alteration of volcanic ash, consisting predominantly of smectite minerals, usually montmorillonite.

Bentonite is a clay generated frequently from the alteration of volcanic ash, consisting predominantly of smectite minerals, usually montmorillonite.

Bentonite deposits are normally exploited by quarrying. Extracted bentonite is distinctly solid, even with a moisture content of approximately 30%. The material is initially crushed and, if necessary, activated with the addition of soda ash (Na2CO3). Bentonite is subsequently dried (air and/or forced drying) to reach a moisture content of approximately 15%. According to the final application, bentonite is either sieved (granular form) or milled (into powder and super fine powder form). For special applications, bentonite is purified by removing the associated gangue minerals, or treated with acids to produce acid-activated bentonite (bleaching earths), or treated with organics to produce organ clays.

The different types of bentonite are each named after the respective dominant element, such as potassium (K), sodium (Na), calcium (Ca), and aluminium (Al). Experts debate a number of nomenclatorial problems with the classification of bentonite clays. Bentonite usually forms from weathering of volcanic ash, most often in the presence of water. However, the term bentonite, as well as a similar clay called tonstein, has been used to describe clay beds of uncertain origin. For industrial purposes, two main classes of bentonite exist: sodium and calcium bentonite.

Drilling Mud : Bentonite is used in drilling fluids to lubricate and cool the cutting tools, to remove cuttings, and to help prevent blowouts. Much of bentonite's usefulness in the drilling and geotechnical industry comes from its unique rheological properties. Relatively small quantities of bentonite suspended in water form a viscous, shear-thinning material. Most often, bentonite suspensions are also thixotropic, although rare cases of rheopectic behavior have also been reported. At high enough concentrations (about 60 grams of bentonite per liter of suspension), bentonite suspensions begin to take on the characteristics of a gel (a fluid with a minimum yield strength required to make it move). So, it is a common component of drilling mud used to curtail drilling fluid invasion by its propensity for aiding in the formation of mud cake.

Binder : Bentonite has been widely used as a foundry-sand bond in iron and steel foundries. Sodium bentonite is most commonly used for large castings that use dry molds, while calcium bentonite is more commonly used for smaller castings that use "green" or wet molds.

Purification : Bentonites are used for decolorizing various mineral, vegetable, and animal oils. They are also used for clarifying wine, liquor, cider, beer, mead, and vinegar.

Bentonite has the property of adsorbing relatively large amounts of protein molecules from aqueous solutions.

Ground Water Barrier : The property of swelling on contact with water makes sodium bentonite useful as a sealant, since it provides a self-sealing, low-permeability barrier. It is used to line the base of landfills to prevent migration of leachate, for quarantining metal pollutants of groundwater, and for the sealing of subsurface disposal systems for spent nuclear fuel.

Medical : Bentonite has been prescribed as a bulk laxative, and it is also used as a base for many dermatologic formulas. Granular bentonite is being studied for use in battlefield wound dressings. Bentonite is also sold online and in retail outlets for a variety of indications.

Pottery : The clay from which pottery is made is described as "plastic" if it can be stretched without cracking, or "short" or non-plastic if it tends to break up when formed. A small amount of bentonite is often added to make a clay mixture more plastic. This makes the clay more easily formed, by methods such as throwing on a pottery wheels and various hand building techniques. Short clay, such as a porcelain mixture consisting only of kaolinite and feldspar, can be formed only by a limited set of methods such as pressing and moulding that do not put the clay under tension. One problem with adding bentonite is that it typically contains minerals that affect the colour of the mix.

Ceramic glazes often contain bentonite. The bentonite is added to slow or prevent the settling of the glazes. It can also improve the consistency of application of glazes on porous biscuits fired ware.

BITUMEN

Bitumen is a low-grade of crude oil which is composed of complex, heavy hydrocarbons. In an oil reservoir, bitumen is a thick, viscous fluid and must be extracted from the ground. When extracting it, a lot of heat and effort must be used to upgrade it to a better product. Although bitumen is hard to extract from the ground, it can bubble naturally to the surface of the Earth in petroleum seeps. These seeps are places where fossil fuels and petroleum products leak out of the Earth instead of being trapped deep below the ground. In these seeps, bitumen, asphalt, and tar bubble up into pools. Additionally, bitumen is the main fossil fuel component of oil sands.. When bitumen combines with asphalt Ines a solid is formed that is useful for paving roads.

Bitumen is a low-grade of crude oil which is composed of complex, heavy hydrocarbons. In an oil reservoir, bitumen is a thick, viscous fluid and must be extracted from the ground. When extracting it, a lot of heat and effort must be used to upgrade it to a better product. Although bitumen is hard to extract from the ground, it can bubble naturally to the surface of the Earth in petroleum seeps. These seeps are places where fossil fuels and petroleum products leak out of the Earth instead of being trapped deep below the ground. In these seeps, bitumen, asphalt, and tar bubble up into pools. Additionally, bitumen is the main fossil fuel component of oil sands.. When bitumen combines with asphalt Ines a solid is formed that is useful for paving roads.

Production : In addition to being found naturally in seeps and the oil sands, bitumen can be produced by removing lighter fractions from crude oil during the refining process. Fractions that are removed are liquid petroleum gas, gasoline, and diesel.

Once crude oil has been extracted from the ground, the production of bitumen can begin. The crude oil is pumped from the storage tanks and through a system that increases the temperature of the crude oil to 200°C. The oil then moves to a furnace, where it is heated even higher to approximately 300°C where it is vaporized partially into a distillation column. Here, the separation of the different components of the crude oil occurs. As lighter components rise to the top, heavy components—including the bitumen—fall to the bottom of the column. This process is known as fractional distillation. Finally, the bitumen is obtained by further distilling the residue in a vacuum distillation column. This type of bitumen is known as straight run bitumen.

Use : Most refined bitumen is used in the construction industry. Mainly, it serves its use in paving and roofing applications. 85% of all bitumen is used as a binder in asphalt for roads, runways, parking lots, and foot paths. Gravel and crushed rock are mixed with thick bitumen, holding it together and it is then applied to roadways. 10% of the bitumen used worldwide is used in the roofing industry as its waterproofing qualities help make roofs function well. 5% of bitumen is used for sealing and insulating purposes in various building materials such as carpet tile backing and paint.

LOW AROMATIC WHITE SPIRIT

White Spirit is a petroleum distillate used as a paint thinner and mild solvent. Mineral spirits have a characteristic unpleasant kerosene-like odor. Chemical manufacturers have developed a low odor version of mineral turpentine which contains less of the highly volatile shorter hydrocarbons. White spirit also can be used for diluting oil colour and cleaning brushes.

White Spirit is a petroleum distillate used as a paint thinner and mild solvent. Mineral spirits have a characteristic unpleasant kerosene-like odor. Chemical manufacturers have developed a low odor version of mineral turpentine which contains less of the highly volatile shorter hydrocarbons. White spirit also can be used for diluting oil colour and cleaning brushes.

We supply premium quality range of LOW AROMATIC WHITE SPIRIT (LAWS)